What is "Casting business"?

In the metal casting business, we produce necessary materials including "coated sand" and "sand core". "Casting" is a process in which the liquid molten metal is poured into the casting cavity which is made of sand. The molten material then cools until it solidifies into the desired shape. It is possible to make a large number of products with complicated shapes at a low cost. Various products such as automobile parts, faucet fittings, manholes, and kitchenware are made of casting and it is no exaggeration to say that our surroundings are full of those products.

Coated sand and Sand core

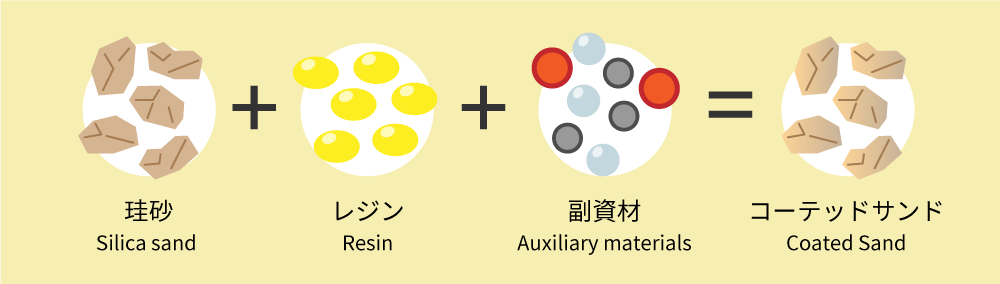

Coated sand, as the name implies, is sand coated with resin (phenolic resin).

In coated sand, sand grains stick to each other and harden due to the chemical reaction of the resin that melts when heat is applied.

Taking advantage of this property, a sand core (nakago) is made by filling coated sand into a desired shape metal mold and heating it at a high temperature.

The sand core is mainly responsible for creating the complex shape inside the casting product.

Tochu's coated sands are trying to meet a wide diverse needs of industry.

About the "coated sand", the performance required varies depending on the shape and material of the casting. Tochu responds to the diverse needs of our customers by developing coated sands. We combine many types of sand such as "recycled sand", "natural silica sand", and artificial sand" and mix with "resin" which has a wide variety of characteristics. Base on our long experience and research, we will continue on producing more valuable and high-quality products upon the customer's request.

Coated sand types and intended use

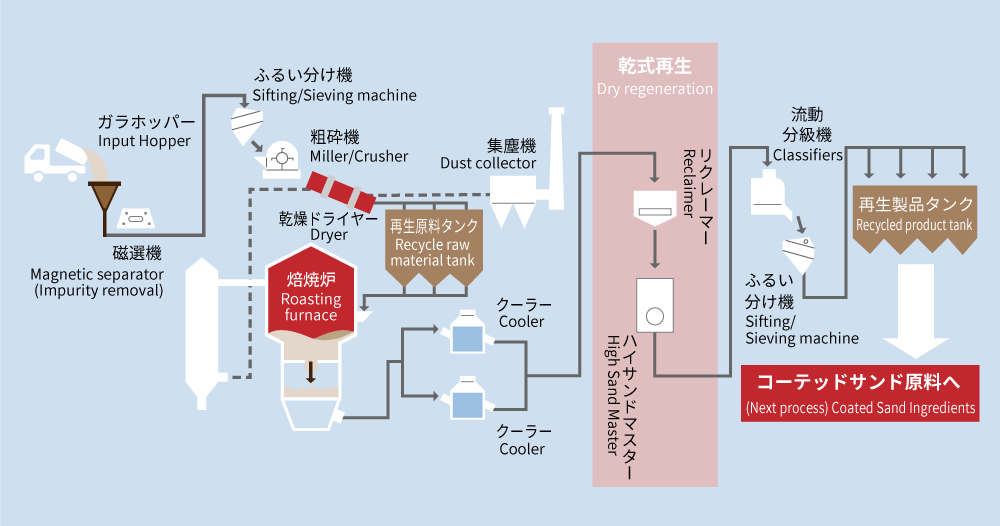

Recycling casted sand as protecting the global environment

"Natural silica sand is a resource mined from the natural and does not spring out infinitely. Tochu has developed a remarkable recycling system by importing the casted-waste-sand from other companies to preserve this limited source-sand. After recycling, by coating with resin, it will be revived as coated sand and delivered to our customers. In this way, we are treating the resources which receiving from the earth carefully.

Recycled sand is superior to natural silica sand in "low thermal-expansion", which is an important property in casting sand, and has large cost merit, so it is highly expected to be casting sand in the 21st century. "